OK1BIL

Pilsen, Czech Republic

OE2BLT

Salzburg, Austria

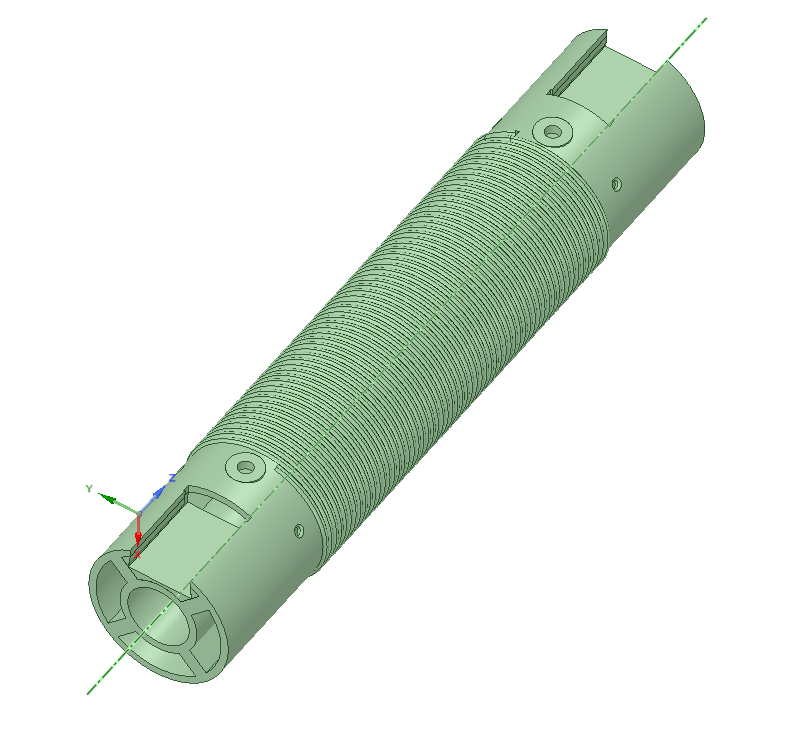

40-20-10m EFHW Loading Coil 3D Model

I was building multiband end fed antenna for 40-20-10m as per instructions on the Nonstop Systems web page Multiband End Fed by Frank N4SPP. I needed to build the loading coil, but the problem was that all materials were too heavy, they were putting excentric load on the fibre glass rod and I did not like the way how the antenna wire was connecting to the coil. So I have created a 3D model for printing that has following benefits:

- it has a thread which helps winding the wire and which separates the turns from shorting,

- it has a center hole which exactly fits my fibreglass mast so that I do not have to secure it in any other way,

- the wire terminals are standard Wago 221 wire clamps.

I do not have 3D printer myself, so the 3D print out was done by a colleague of mine who has the Prusa i3 MK3 3D printer. Care has to be taken to melt the individual layers properly as our early prototypes suffered from breaking in half. If the print out is done properly, then the coil former can withstand quite heavy stress. My original coil traveled with me on various places for a good one year before my mast collapsed once and the coil fell from 10m on concrete surface. The depicted copy is the new replacement.

I do not have 3D printer myself, so the 3D print out was done by a colleague of mine who has the Prusa i3 MK3 3D printer. Care has to be taken to melt the individual layers properly as our early prototypes suffered from breaking in half. If the print out is done properly, then the coil former can withstand quite heavy stress. My original coil traveled with me on various places for a good one year before my mast collapsed once and the coil fell from 10m on concrete surface. The depicted copy is the new replacement.

Specifications

Coil inductance: 34uH

Wire between 64:1 balun and the coil: 10.1m

Wire between coil and antenna tip: 1.85m

The Wago clamps are holding in place only by presure of the 3D printed material, there is a little notch helping this. This is the method even the original Wago clamp holders are using. The screws do not tap to the plastic material, but there is a nut inside of the coil former. It has to be held in place by small pliers before the thread taps.

Update 2020: 30m-17m version

I wanted to have coverage of 30m and 17m with the same concept of an antenna. I have just simply tried in the backyard empirically and it turned out that with the same coil, the two bads can be covered!

Coil inductance: 34uH (same coil as above)

Wire between 64:1 balun and the coil: 7.48m

Wire between coil and antenna tip: 0.83m

Downloads

coil-former-v3c-final.rsdoc RS DesignSpark Mechanical 4.0 (source)

coil-former-v3c-final.stl STL Export